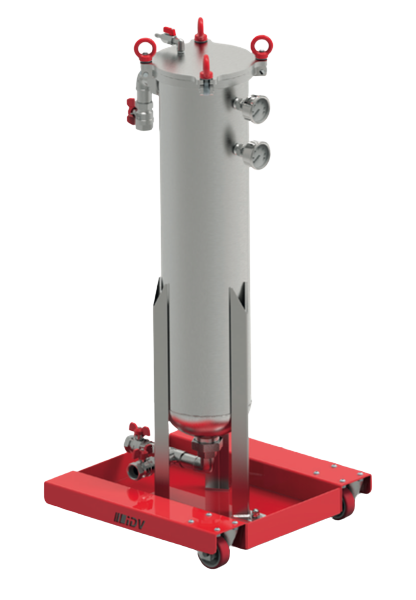

Microfiltration creating a competitive advantage

Microfiltration creating a competitive advantage

What are we doing?

Microfiltration creating a competitive advantage

We help users of CNC machining centers keep their cooling lubricants in perfect condition, improve quality and cut maintenance costs in half at the best possible cost.

We reduce your cutting oil costs

We increase your process quality

We protect the environment

HALF COSTS, INCREASED QUALITY

We help users of CNC machining centers keep their cooling lubricants in perfect condition, improve quality and cut maintenance costs in half at the best possible cost.

THE MOST COMMON PRODUCTION PROCESSES OF MICROFILTRATION

Machine tools and tools have shown great improvement in recent years, as have cooling oils. New milling cutters, high-precision controls, and highly advanced oils and additives have elevated mechanical engineering to a class of performance and tolerance that seemed unattainable fifteen years ago.

The cleanliness of the refrigeration oil has a direct impact on process reliability, quality and costs in all processes where refrigeration oil circuits are used.

WHY to USE

- To eliminate health problems among your employees

- To ensure the availability of your machines

- To increase the service life of your tools

- To improve the surface quality by up to 300%

- You should use it to save at least 75% of maintenance, replacement and disposal costs

MICROFILTRATION IN CNC MACHINING

Modern CNC machine tools are costly investments that can only be recouped with long-term reliable operation and minimal maintenance costs. However, an important factor is often overlooked: the cutting oil emulsion.

SAYECK INNOVATIONS FİLTRE SİSTEMLERİ ANONİM SİRKETİ